Surface finish or roughness is the texture measurement of the surface. It is the definition of how far the vertical deviations are from the ideal. A CNC-machined surface is smooth if these deviations are minimal and rough if they are significant.

In most instances, particularly in engineering projects, a part’s surface finish is critical because it affects aesthetics and functionality. For instance, smooth surfaces have lower friction coefficients and last longer than rough surfaces.

This article will highlight the CNC surface finish concept, from the techniques used to the factors affecting surface finish.

What Is CNC Surface Finish?

CNC surface finish is the definition of the physical attributes of a CNC-machined surface – roughness, smoothness, and others. It is measurable using elements such as Center Line Average (CLA), Roughness Average (Ra),

Root Mean Square (Rq), sampling length number (N), and Maximum Height (Rt).

Center Line Average (CLA)

This is the average height taken from all the peaks and valleys of surface roughness across a measured length, as measured from a central line. Smoother surface finishes have lower CLA, and vice versa.

Another name for CLA is Roughness Average (Ra), but CLA is mostly used in the United Kingdom in most contexts. This measure of surface roughness is usually given in microinches (µin) or micrometers (µm).

Root Mean Square (Rq)

Also denoted as RMS, this measure of surface finish is found by calculating the square root of the mean of the standard deviation squares. This is a different way of measuring surface roughness, this time giving more emphasis to deeper valleys and taller peaks in comparison to Ra.

Total Roughness (Rt)

This is the total length of the difference between the deepest valley and the highest peak in the evaluation length. This measure is given in microinches (µin) or micrometers (µm).

Sampling Length Number (N)

An evaluation length of a surface finish measurement can have several sampling lengths. The number of these lengths is indicated by N, and can affect the accuracy of surface finish measurements.

Difference Between Surface Finish And Surface Finishing

The concepts of surface finish and surface finishing in CNC machining can be easily confused, yet they refer to different aspects. As noted above, surface finish refers to a surface’s texture.

On the contrary, surface finishing is the act of manipulating the surface to achieve a desired surface quality.

CNC Surface Finish Options

Every CNC-machined part has its standard as-machined finish, but it may require further processing to enhance aesthetics and/or functionality. When the cutting tool interacts with the part, it leaves the surface with marks, tiny or large.

While some engineering applications are okay with the standard machine finish, many instances require enhanced surface finishes. Popular types of surface finishes at ProleanTech are anodizing, bead-blasting, powder coating, and polishing.

As-Machined

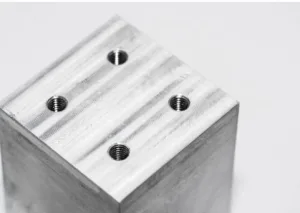

As-machined surface on a metal block

This is the standard machine finish assumed by every CNC-machined part at the end of the process. Of course, there will be marks from the cutting tool, but sometimes, the part can function correctly as it is. Being rough and lacking a protective coating can put off some users, depending on their aesthetic preferences and functional requirements.

With a standard machine finish of about 3.2 μm and very tight dimensional tolerance, as-machined parts’ surface finishes are highly regarded in some quarters. Remember, the part is also relatively more affordable because of the avoided post-processing.

Anodizing

Anodized CNC-machined parts

This electrochemical process, typically performed on titanium or aluminum alloys, hardens the machined part’s surface for higher durability. It entails submerging the part in an electrolyte bath, acting as an anode.

Placing a cathode in the bath completes the circuit, prompting the alloy’s atoms to combine with ions from the electrolyte. This ultimately causes the formation of a protective layer on the alloy’s surface.

Anodizing surface finish examples can be either Type II or Type III.

Bead-Blasting

The satin or matte surface finish on many CNC machined parts is often achieved through bead-blasting. This method comprises a pressurized gun shooting countless glass beads on the CNC machined part. Unlike other finishes like powder coating and anodizing, bead-blasting is neither chemical nor mechanical. It is purely physical.

Powder Coating

Powder coating is the formation of an attractive, protective, and durable layer or layers of chromating or phosphating material. This coat, which is also corrosion-resistant, works with all metal categories and is extremely durable.

Powder coating in process

Polishing

This is another method of enhancing the functionality and appearance of a CNC-machined surface. It is a straightforward process that entails refining the surface for better functionality, aesthetics, and texture.

There are three types of polishing, namely chemical polishing, electrochemical Polishing, and mechanical polishing.

The Role Of Machine Finish Chart

Manufacturers use the machine finish chart to determine the best surface finish for their CNC-machined parts. The machine finish chart can be used as a guide to choose the ideal surface finish before machining, or after the process to confirm if the recommended surface finish has been achieved.

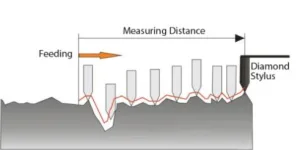

Some tools that go in tandem with the machine finish chart are surface roughness comparator, profilometer (contact or non-contact), and stylus-type surface tester, among others.

Measuring surface roughness

Factors Affecting CNC Surface Finish

The applied CNC process matters, but other factors equally influence the quality of a CNC surface finish. The material properties are on top of the list, and are joined by the cutting speed, depth of cutting, and the feed rate.

An often forgotten factor is the machine itself, considering elements such as sturdiness, vibrations, coolant effectiveness, and general tooling.

| Factor | Effect on surface finish |

| Coolant effectiveness | Effective cooling minimizes thermal effects and improves surface finish |

| Cutting speed | Higher cutting speed can enhance surface finish quality, albeit at the risk of heat build–up |

| Depth of cut | Shallower depths make fewer surface marks and enhance the finish |

| Feed rate | Finer surface finishes are usually achieved at lower feed rates |

| CNC machine sturdiness | A rigid machine is less prone to chatter and deflection, hence, good for surface finish |

| Material properties | Harder materials may produce smoother cuts due to less smearing |

| Setup and tooling | The correct selection of tools and quality fixturing enhances CNC surface finish |

| Vibrations | Reduced machine vibration ensures smooth, precise cuts |

In Conclusion

The CNC surface finish of a CNC machined part presents many advantages. Most businesses are aware of this, but struggle when it comes to choosing the perfect finish for their products.

This is understandable because there are numerous options in the market. When in such a situation, the best strategy is to consult a renowned provider of CNC Machining Services for guidance.

FAQ”s:

What is the standard surface finish for CNC?

The standard surface finish for CNC machining is the as-machined version, which is about Ra 3.2 µm (125 µin).

What does 0.8 surface finish mean?

A 0.8 surface finish means 0.8 micrometers roughness average (Ra), which is smooth and fine.

Which technique gives a better surface finish?

Of all the machining techniques, grinding tends to give the best surface finish. The technique can achieve a Ra value of 0.2 µm or below.

What are the two most common methods for measuring surface finish?

The two most common methods for measuring surface finish are contact profilometry and optical (non-contact) profilometry.

Information contained on this page is provided by an independent third-party content provider. Binary News Network and this Site make no warranties or representations in connection therewith. If you are affiliated with this page and would like it removed please contact [email protected]

Comments